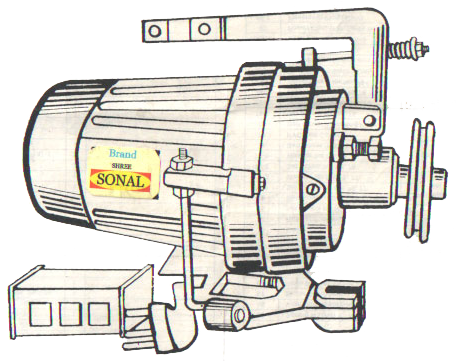

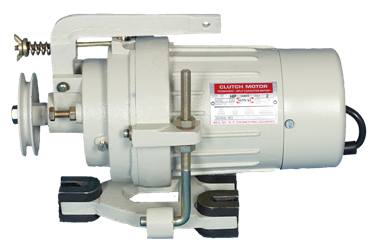

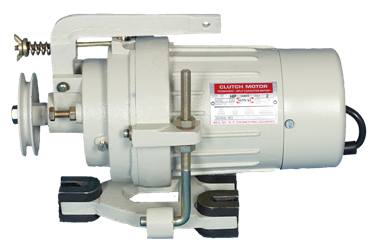

Clutch Motor

We Offer:

We Offer:

PERFORMANCE : The motor is especially designed with powerful performance for industrial sewing machines purpose.

SMOOTH ROTATION : Vibration and noise are minimized.

LOW TEMPERATURE RISING: The temperature rising of the motor is extremely low.

ACCURATE CLUTCH OPERATION: The size and weight of the flywheel eliminate speed reduction when it engaged with the clutch. Heavy-duty lining material prevents any slipping.

ACCURATE CLUTCH OPERATION: The size and weight of the flywheel eliminate speed reduction when it engaged with the clutch. Heavy-duty lining material prevents any slipping.

Therefore the accurate clutch operation permits instant starting and stopping of the sewing machine

ADJUSTABLE CLUTCH HEADThe operating lever can always be kept in line with the pitman rod and foot treadle.

Loosen the bracket holding screw so that the pulley side can end of bracket rotates freely. Now adjust the clutch lever to the most suitable operating position.

Then, tighten the bracket holding screw and commence operation.

BELT TIGHTENER: The motor is provided with a belt tightener of American dimensions. The tension of the belt is easily adjusted by simply loosening the adjustment nut.

SMOOTH ROTATION : Vibration and noise are minimized.

LOW TEMPERATURE RISING: The temperature rising of the motor is extremely low.

ACCURATE CLUTCH OPERATION: The size and weight of the flywheel eliminate speed reduction when it engaged with the clutch. Heavy-duty lining material prevents any slipping.

ACCURATE CLUTCH OPERATION: The size and weight of the flywheel eliminate speed reduction when it engaged with the clutch. Heavy-duty lining material prevents any slipping.

Therefore the accurate clutch operation permits instant starting and stopping of the sewing machine

ADJUSTABLE CLUTCH HEADThe operating lever can always be kept in line with the pitman rod and foot treadle.

Loosen the bracket holding screw so that the pulley side can end of bracket rotates freely. Now adjust the clutch lever to the most suitable operating position.

Then, tighten the bracket holding screw and commence operation.

BELT TIGHTENER: The motor is provided with a belt tightener of American dimensions. The tension of the belt is easily adjusted by simply loosening the adjustment nut.

- Jute Bag

- PP/PE Woven Cloth Bag

- Hosiiery Motor

- Ready-Made Garments Motor

- All Type of Bag Stitching Machine Motor

- Plastic Woven Sacks

| Output | 0.25 H.P. | 0.33 H.P. | 0.50 H.P.s | 0.75 H.P. | 1 H.P. | 2 H.P. | ||||||||||||||||||

| Poles | 2 | 4 | 2 | 4 | 2 | 4 | 2 | 4 | 2 | 4 | 2 | 4 | ||||||||||||

| Rating | CONTINOUS | |||||||||||||||||||||||

| VOLTAGE (V) |

SINGLE PHASE 100-250 V THREE PHASE 200-440 V | |||||||||||||||||||||||

| FREQUENCY (C/S) |

60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| SPEED(rpm) | 2850 | 3450 | 1425 | 1725 | 2850 | 3450 | 1425 | 1725 | 2850 | 3450 | 1425 | 1725 | 2850 | 3450 | 1425 | 1725 | 2850 | 3450 | 1425 | 1725 | 2850 | 3450 | 1425 | 1725 |

| NET WEIGHT (kg) |

13.4 | 19 | 20.5 | 21.1 | 22.2 | 34.4 | ||||||||||||||||||

| GROSS WEIGHT (kg) |

14.2 | 20 | 21.5 | 22.1 | 23.2 | 36 | ||||||||||||||||||

| MEASUREMENT (in) |

15×10×10 | 25×12×12 | 17×12×12 | 17×12×12 | 17×12×12 | 20×16×15 | ||||||||||||||||||

| STANDERED ACCESSORY |

FIXING BOLTS |

PULLEY PSH BUTTON BUTTON SWITCH & CABLE |

PULLEY SIZE (mm)45,55, 65,75,85,100 |

|||||||||||||||||||||